REGENAIR ® Regenerative Blowers

The separator removes liquids from the gas stream in a soil vapor extraction process, to help protect both blower and vapor treatment system from corrosion and mineral deposit buildup. The separator is located between the extraction wells and the blower. An inline

filter is installed between separator and blower.

The separator removes liquids from the gas stream in a soil vapor extraction process, to help protect both blower and vapor treatment system from corrosion and mineral deposit buildup. The separator is located between the extraction wells and the blower. An inline

filter is installed between separator and blower.

Practical Design Engineered to remove and contain moisture ranging from a fine mist to slugs of water from blower inlet air streams, Gast separators incorporate a cyclonic action which results in a very high degree of efficiency. A floating ball valve which closes when the liquid level becomes too high prevents collected liquid from overflowing back into the air stream. When the float valve closes, an integral vacuum relief valve opens, admitting air to cool the blower and prevent overheating.

Rugged Construction Gast separator drums are made from ribbed heavy gauge cold-rolled steel, with heavy steel inlet, drain and float switch ports welded to the drum wall. Drum interiors are epoxy coated to resist abrasion, corrosion and chemicals, while the drum exterior is coated with durable urethane. For ease of connection, the outlet port of female pipe threaded. The heavy – duty 304 stainless steel ball float resists chemicals. Maximum rated vacuum is 22 inHg (299 inH₂O).

Included is a pilot operated precision relief valve capable of functioning over a wide duty range. This vacuum relief valve is designed and built to proven reliability and durability standards. Moving parts are nickel plated

for corrosion resistance and smooth operation. Explosion proof AJ213 float switch is optional; single pole double throw, electrical rating 5 amp @ 125/250 VAC, 1” NPT mounting.

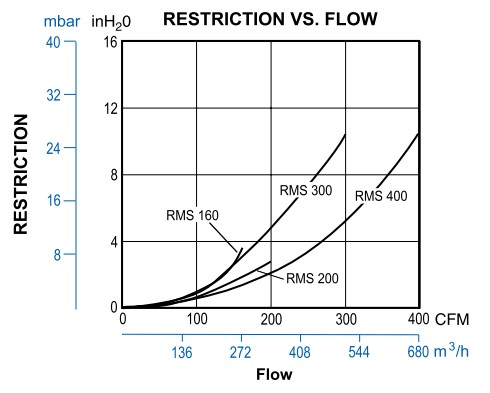

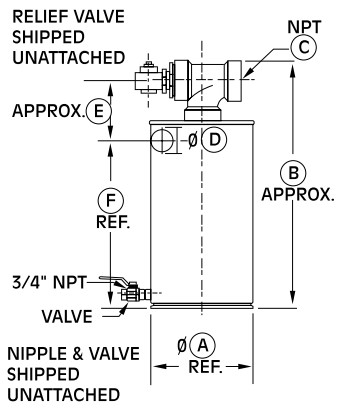

| Part No. | Liq. Cap.(gal.) | A(dia.) | Dim. B | C(NPT) | D(dia.) | Dim. E | Dim. F | Used On |

|---|---|---|---|---|---|---|---|---|

| RMS160 | 10 | 14.8'' | 37.5'' | 2'' | 2'' | 7.5'' | 26.6'' | R3, R4, R5 |

| RMS200 | 19 | 19.7'' | 35'' | 2'' | 2'' | 7.5'' | 26.6'' | R4, R4H, R4P, R5 |

| RMS300 | 19 | 19.7'' | 35'' | 2.5'' | 2.5'' | 7.5'' | 26.6'' | R4H, R4M, R5, R6, R6P, R6PS, R7H |

| RMS400 | 40 | 24'' | 44'' | 3'' | 3'' | 9.7'' | 29'' | R6PP, R4M, R6, R6P, R7, R7S, R7P, R7H, R9, R9S |

MECHANIKA Co., Ltd. Head office 255/1 Floor 4 Charoen Krung Road, Ban Bat Subdistrict Pom Prap Sattru Phai District, Bangkok 10100